INNOVATION with quality.

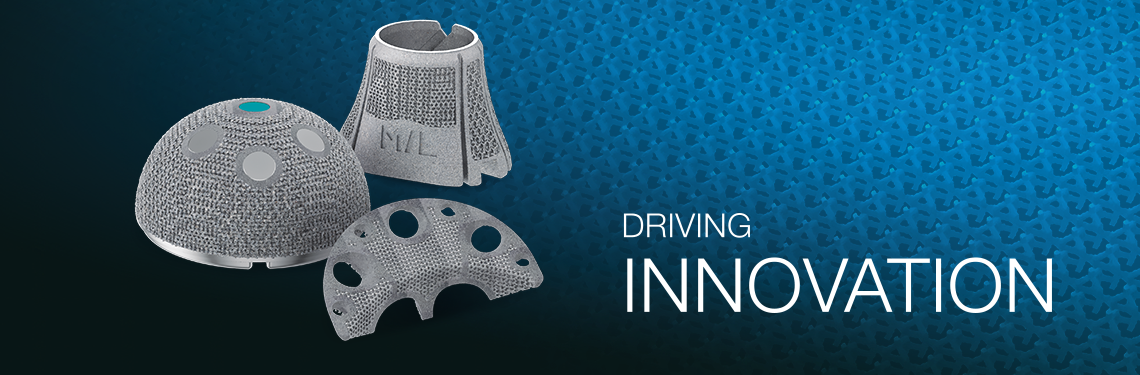

Development, materials, production – there are many factors that contribute to the quality and durability of a prosthetic joint. We have them all firmly in focus.

- Training: At LINK, training is provided to the German standard, combining college attendance with working in the company. This means we can be sure of recruiting the next generation of skilled and qualified staff members.

- Development: Our constantly growing team of development specialists, known as DERU, is dedicated to developing new products and identifying areas where we find potential for improvement. They are the driving force behind innovation at our company.

- Production: Our strength lies in the combination of manufacturing expertise and seamless quality control throughout every stage of the production process. From investment casting of the raw prosthetic joints in our own VACUCAST foundry to finishing and packaging at our orderstedt plant, the entire production process is in-house.

- German quality – worldwide: In addition to our manufacturing operations in Germany, we also aim to be local for our international customers. Here our production plant in Beijing has a major role to play. We are also planning to establish further international operations.

Produkter

Företag

Standardvillkor (köp, försäljning) | Juridisk information | Användarvillkor | Integritetspolicy | Meddelande om skydd av personuppgifter för arbetssökande

2025 © Waldemar Link GmbH & Co. KG