We train our employees of the future.

That is how we create and develop our skilled and qualified team.

We currently offer traineeships in the following vocations:

- Training at our in-house training workshop

- Skilled instructor: Ensuring direct, personal supervision, and always an open ear for the each individual

- We place equal importance on all aspects of the training provided: With us you will learn skills such as turning, milling, and grinding, both manually and on ultra-modern CNC machines

- Learn to assemble and adjust components, use testing procedures, and control and correct machining centers

- Our trainees regularly complete their training with outstanding results

- Traineeships last 3.5 years

- If a trainee’s work is particularly good, the traineeship can be shortened by six months

- Trainees attend vocation school at Norderstedt (BBZ Berufsbildungszentrum)

- Practical training is provided at our production plants in Norderstedt

Requirements:

• Good secondary school (Hauptschule/Realschule) grades

• Manual dexterity, accurateness, and perseverance

Further information about traineeships:

• Starting August 1 each year

• Final examination is held by the Lübeck Chamber of Industry and Commerce

• Trainees are paid at the standard rate

Reliability, punctuality, and respect for others are, of course, a requirement.

- Traineeships at the Hamburg and Norderstedt sites

- Skilled instructor: Ensuring direct, personal supervision, and always an open ear for the each individual

- The following departments form the core of the training provided: Customer service - domestic and export, bookkeeping, materials management, human resources, controlling, marketing

- As training progresses, you will gradually assume responsibilities, thus providing you with ideal preparation for working life

- Our trainees regularly complete their training with outstanding results

- Traineeships last between 2.5 and 3 years

- If a trainee’s work is particularly good, the traineeship can be shortened by six months

- Trainees attend vocational school at Hamburg Eimsbüttel

- Attendance at vocation school is organized in blocks

Further information about traineeships:

- Starting on August 1 each year

- The final exam is held by the Hamburg Chamber of Industry and Commerce

- Trainees are paid at the standard rate

Reliability, punctuality, and respect for others are, of course, a requirement.

Training at LINK in the words of a trainee:

Telligmann K.: Expected completion of Industrial Mechanic training: June 2018

What are the benefits of a traineeship?

Waldemar Link GmbH & Co. KG provides training in order to recruit new members to our team, and with great success. The company has its own training workshop, which is used to provide direct individual supervision for the duration of the traineeship.

What are the highlights?

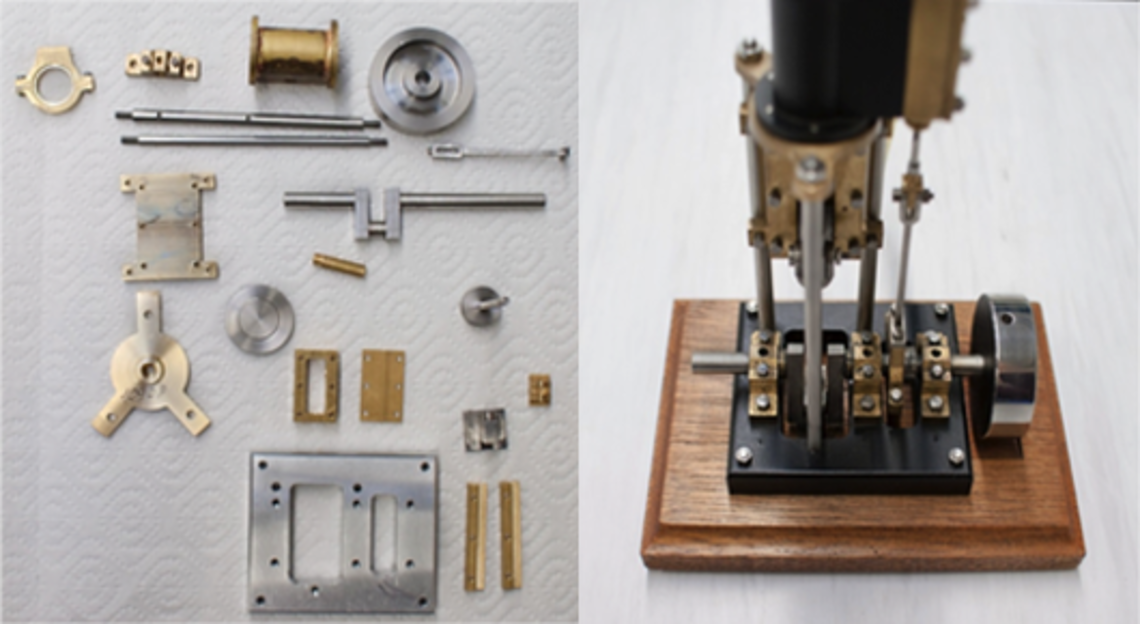

Special mention should be given to the various projects in which our trainees fabricate, assemble, and adjust everything themselves, i.e. from reading the drawing and producing the basic dimensions through to tightening the last screw. In the process, they familiarize themselves with how components function. Opposite are two pictures from the Herkules Project.

Brief description of a traineeship

In the first year and a half, basic skills such as filing, drilling, turning, milling, and testing are taught. Projects give trainees the opportunity to learn how to assemble and adjust a component. Then trainees spend time in all the departments and learn how to operate state-of-the-art CNC machines.

Conclusion

I find the traineeship at LINK very interesting and varied. We all get on really well together here. Our instructors mentor us throughout our traineeship and make sure that the actual training is tailored to suit each individual person. If we have any issues, they are always there to help us. In the first eighteen months we mainly learn basic skills so that we can accumulate enough experience to be ready to sit the intermediate exam. We attend vocational school in blocks, so Mr. S. prepares us very thoroughly. Then we spend time working in the various departments, such as CNC, grinding shop, assembly, etc. I found it really interesting to see how the products gradually take shape, so when you see the finished item, you understand how it was produced. Then it is already time for the final exam, for which we are prepared very well by our instructors.